The increasing importance of sustainable and transparent supply chains is a trend affecting our daily business practices. So in this post, you will be able to learn how we at Jolon Textile bring sustainability to our operations. Since we as a global brand, care a lot about the planet we live on and the future generations to come.

Background

1. Environment

By incomplete statistics, billion tons wastage of plastic bottles/products & cloths/textiles were disposed of which cover our planet. As a result, our environment and our planet are in mourning. Because the textile industry is the world’s second-largest environmental polluter after the petroleum industry. Since it emits 1.2 billion tons of greenhouse gases every year. And from that 10% of the global total, textile fiber, yarn, and fabric manufacturers are the main ones. For example, statistics show that 34% of the microplastics wastage found in the oceans comes from the textile/clothing industry. Also, most of them are made of polyester, polyethylene, acrylic, elastane, etc.

So selecting more sustainable alternative raw materials and developing more sustainable methods in the production chain is the key turning point for textile manufacturers/distributors/wholesalers/brands.

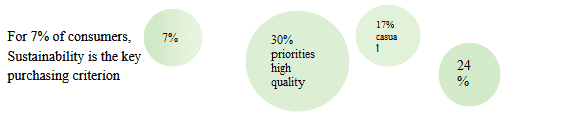

2. Public Awareness

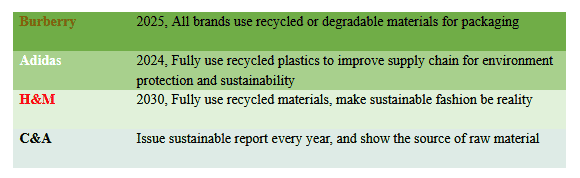

3. Leading brands flags

4. SDG (Sustainable Development Goals)

In fact, during a United Nations summit, 193 countries announced till 2030, completely solve the problems of sustainable development in a comprehensive way by balancing society, economy, and environment.

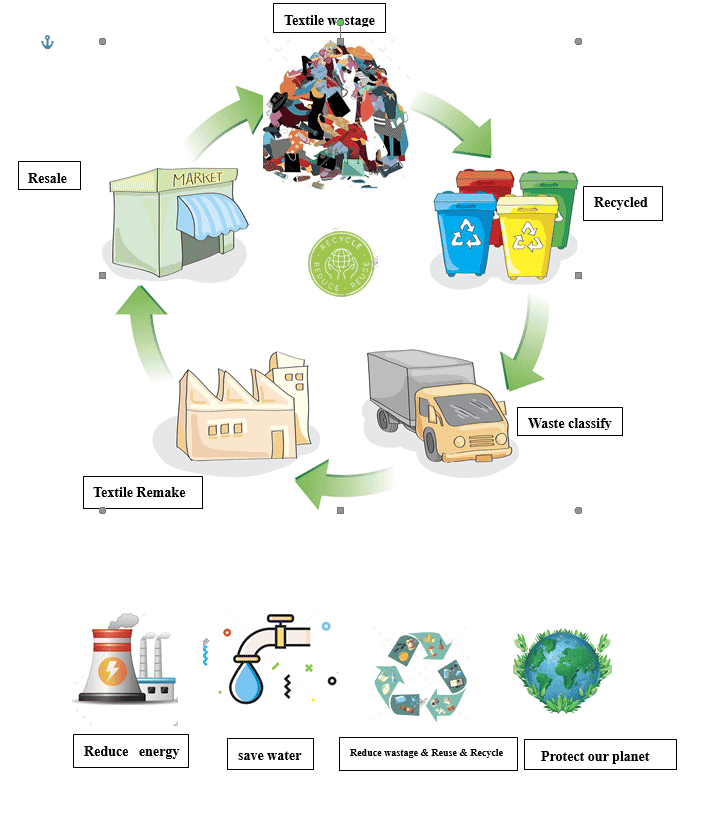

5. Circle Of Sustainability

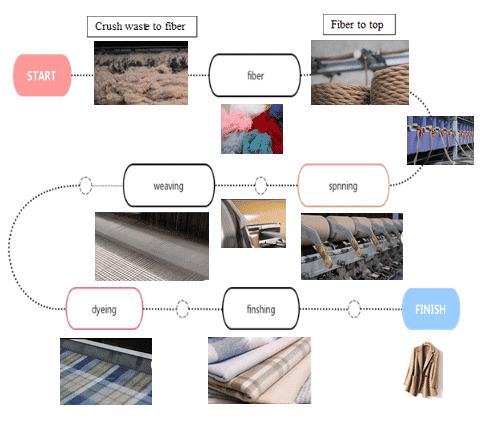

Recycled textile wastage /plastics, crush to fiber, and remake to fabrics/cloth to sell again. Therefore there are many technical processes are required in this whole chain.

Our Mill Sustainable System

- Keeps sustainability as a core focus.

- Apply in every step of the fabric production chain.

- Follow the Global recycled standard: the GRS is an international, voluntary, full product standard that sets requirements for third-party certification of recycled content, chain of custody, social and environmental practices, and chemical restrictions.

1. Recycled Production Process

2. Environmental practices

- Take a high awareness of environmental protection, apply global recycled standards/countries and/or local regulations to all related production steps.

- Inspect the wastewater/gas system regularly, so strictly follow related emission standards.

- Reduce energy consumption such as electricity, steam, and also the usage of raw materials.

- Apply chemical restrictions in the whole supply chain as in the raw material /dyeing step.

- Maximize recycled content percentage, transparent supply by updating new technology, etc.

3. Social practices

- Good working conditions include the fire fighting part, emergency part, medicine part, and GRS special zone.

- Apply International labor standards, also national and/or local legislation or GRS requirements.

- Labor training both in safety and specialized skills.

- 66% of fashion brands believe that sustainable development is the key to future fashion. Since a lot of people care about what they wear come from as to past generations.

- 77% of fashion brands are already developing or plan to develop sustainable fashion products in 1-2 years. So the end goal of many brands these days is to become 100% sustainable.

- 70% of fashion brands want to attract consumers with a sustainable brand image. Because of this, you can see a lot of brands changes into renewable and sustainable pathways,

- 69% of fashion brands believe that the supply chain is very important in promoting sustainable fashion. Because many customers do a lot of research before they buy clothes these days. And supply chain is one of the subjects that these customers consider the most.

- 57% of fashion brands believe that consumers are willing to pay a 6%-15% surcharge for sustainable fashion products. As a result, many believe going sustainable will be profitable in the long run.

In the next 2-to 3 years, sustainability will become the highlight of the development of the fashion industry. And in fact, already be for us and many brands.

Jolon Textile – Leading The Wool Manufacturing Industry Towards Sustainability

If you are planning to buy high-quality sustainable woolen fabrics, then Jolon Textiles is the place to be. Therefore contact us before you buy from us to receive all the information regarding our product and services. And we will also provide you with exclusive quotes to meet all your requirements regarding wool and other fabrics. Therefore if you come to us we will guarantee you an excellent service that you will not find anywhere else in this industry.

For more information – info@jolontextile.com